Do You Need Help? Here Us : Tel : +86 595 22486398

Do You Need Help? Here Us : Tel : +86 595 22486398

This is the situation of the electric dump truck industry in 2044!

July 28, 2025Electric dump trucks are on the cusp of significant growth and are expected to become a $15 billion industry by 2044, according to a new report from IDTechEx, Electric Vehicles in Mining 2024-2044: Technologies, Players and Forecasts.

Electric dump trucks will be key to achieving emissions reductions in the mining industry and helping mining companies achieve their sustainability goals. Dump trucks make up nearly a quarter of the global mining fleet, but are also by far the largest and most emitting vehicles, accounting for more than 90% of mining industry vehicle emissions and more than 174 megatonnes of CO2 per year. The electrification of these vehicles is progressing steadily, at a pace that has attracted the attention of key players across the industry, including mining companies, OEMs and battery suppliers.

Compared to other mining vehicles, especially on-road vehicles, dump truck electrification is still in its infancy, with only one or two electric dump trucks produced each year. The total number of such vehicles will not reach double digits until 2023, and most of them are prototypes and test models developed by mining companies themselves and independent converters (not OEMs). They repurpose existing diesel machines to install batteries or fuel cells to achieve zero-emission operation. First Mode and WAE are two of the most active companies in this field and are expanding their conversion capabilities in the near term.

Recently, major mining OEMs have entered the electric dump truck space, seeking to develop and commercialize electric versions of their existing vehicles in-house. These include two of the world’s largest mining OEMs, Caterpillar and Komatsu. Caterpillar has built a 793 electric prototype that is currently being tested with the goal of commercializing it by 2027. Komatsu’s 830E electric is also in a similar stage of development with the goal of entering production by 2030.

The increase in OEM interest in electric dump trucks can be attributed to the growing demand from mining companies. Many of the world’s largest mining companies have signed agreements with converters and OEMs to supply electric dump trucks when the technology becomes commercialized. These companies are increasingly realizing that electric dump trucks are not only more environmentally friendly and provide safer working conditions, but they can also provide significant savings in total cost of ownership.

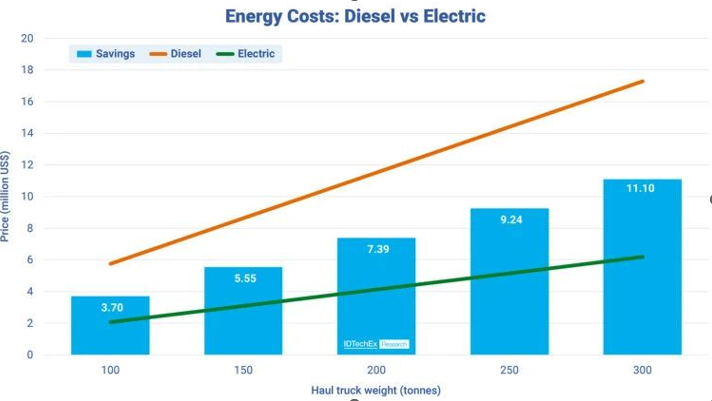

The largest portion of the total cost of ownership savings comes from replacing diesel with cheaper electricity. Dump trucks have the most intensive duty cycle of all the vehicles on a mine site, operating an average of 20 hours a day, consuming large amounts of diesel in the process. Therefore, any cost reduction will compound significantly over the 10-year life of the truck. A 150-ton dump truck can save more than $5.5 million in energy costs alone. This applies broadly to vehicles of all weights, with heavier trucks offering greater benefits, highlighting the potential savings that can be generated when an entire dump truck fleet is electrified.

Regardless of the cost savings, electric dump trucks will be expensive. Dump truck batteries are large and expensive, requiring multiple replacements over a 10-year period. The question remains: Will the energy savings be enough to offset the battery premium?

The large batteries required for electric dump trucks were probably the biggest technical and financial bottleneck holding them back, but now they are fully developed and competitively priced for wider use. These batteries are typically over 1 MWh, with the largest approaching 2 MWh. IDTechEx has collated a database of all existing electric dump truck models, showing that current vehicles still have a run time of less than 6 hours on a single charge. For a 150 tonne dump truck to run that long, a battery pack of over 1700 kWh would be required, costing over $500,000.

The energy savings will easily outweigh the additional cost of a single battery. However, IDTechEx estimates that electric dump trucks will require an average of five additional batteries per vehicle, costing an additional $2.6 million.

Other cost factors also affect the total cost of ownership of an electric dump truck. On average, a 150-ton truck will save about $340,000 in maintenance costs over its lifetime. However, the electric drivetrain costs $70,000, plus IDTechEx estimates that labor costs for the conversion are $360,000. While these are relevant and significant costs, they are insignificant compared to the expense of diesel or batteries and are not a key determinant of the economics of a dump truck.

All in all, despite the need for multiple expensive battery replacements, the total cost of ownership still favors electrification. Mining companies will be able to save nearly $2.5 million per electrified dump truck, and the truck will pay for its increased capital expenditure in less than 3 years. Given that the number of electric dump trucks is still small, there is a lot of room for battery costs to fall below the $300/kWh estimated by IDTechEx. At the same time, as cycle life improves, the frequency of battery replacement will decrease. As these things happen, the economic advantage of electric dump trucks over diesel trucks will become more significant.

If electric dump trucks are so economically attractive, why aren’t they already commonplace? First and foremost, the batteries need to be sized and durable enough to meet the demands of a dump truck’s duty cycle while still remaining relatively affordable. This has only recently been achieved by battery suppliers such as CATL, ABB and Northvolt, and the industry is now expanding to do just that. Dump truck battery development is in its infancy – a variety of designs and chemistries are being used to meet performance requirements, but there is no industry-wide consensus.

Productivity is another key issue in adopting electric dump trucks. Currently, it is impossible for electric trucks to match the uptime of diesel trucks. Diesel trucks can be refueled in as little as 10 minutes per day, while electric vehicles need to be recharged multiple times a day, taking a total of two to three hours. Mining companies will be reluctant to adopt a technology if it means sacrificing the productivity and output of their operations.

Electric dump trucks are more than 10% more efficient than diesel trucks (faster speeds, less maintenance), which can go some way to minimizing the impact of electrification on productivity. However, OEMs still hope to eliminate any impact entirely by maximizing battery runtime and using faster charging methods.

Charging itself is a big hurdle for electric dump trucks. To maintain the productivity that mining companies demand, dump trucks need to be charged at rates of 1 to 3C. High charging rates compromise the cycle life of the battery, which will require more frequent battery replacements. Whether the various battery technologies from different suppliers can sustain charging at such high rates remains to be seen.

This will also come with extremely high energy requirements. Charging a 1700 kWh battery at a rate of 3C would require a connection of over 5 MW, equivalent to the output of two offshore wind turbines. Charging at such a rate would require dedicated power plants and extensive upgrades to the local power infrastructure, which would be costly for mines. Given that the price premium for electric dump trucks remains high, mines may be unwilling or unable to afford the deployment of vehicles and infrastructure. However, IDTechEx expects that mines will increasingly implement this infrastructure through the economic attractiveness of electric dump trucks and the wider electrification of mining vehicles and operations.

OEMs are committed to electric dump trucks in their long-term strategic visions, and mining companies have shown a willingness to adopt them as quickly as possible. The total cost of ownership advantages offered by electric dump trucks cannot be ignored, and continued developments in batteries and chargers will eliminate many of the current doubts about these vehicles. With lower operating costs, higher productivity, and better environmental performance, electric dump trucks are the clear winners for the future of mining.

Source: Machinery Intelligence, IDTechEx report "Electric Vehicles in Mining 2024-2044: Technologies, Players and Forecasts"

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Add: Pudang Village, Xiamei Town, Nan'An City, Quanzhou, Fujian, China

Quanzhou Huamao Machinery Equipment Co.,Ltd All Rights Reserved.  Network SupportedSitemap | blog | Xml | Privacy Policy

Network SupportedSitemap | blog | Xml | Privacy Policy