Do You Need Help? Here Us : Tel : +86 595 22486398

Do You Need Help? Here Us : Tel : +86 595 22486398

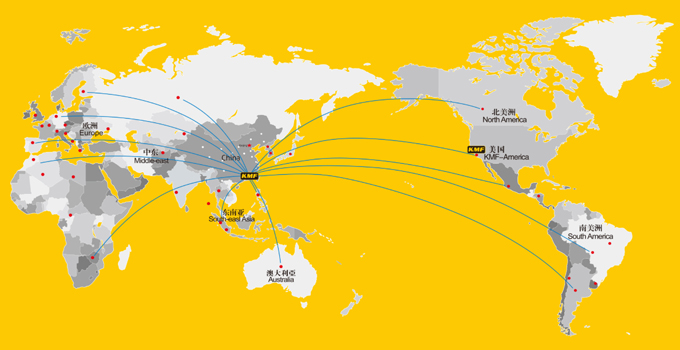

Quanzhou Huamao Machinery Equipment Co., Ltd. (Huasheng Machinery, KMF for short), since its establishment in 2004, has been committed to the research and development and production of various types of construction machinery crawler tracks and chassis parts for vehicles. It is a company integrating forging, casting, machining, A production-oriented enterprise integrating heat treatment and assembly.

Read More

Our Track Frame for Excavators is meticulously designed to meet the demands of heavy-duty excavation tasks. Engineered with durability and efficiency in mind, this track frame enhances the overall performance of your excavator in various operating conditions.

Meticulously crafted for optimal suspension performance, this assembly ensures precise damping, stability, and durability.

The excavator bucket has different types which for standard bucket, heavy duty bucket, rock bucket. We provide customers with first-class products and services.

The crawler assembly of excavator adopts precision forging of alloy wear-resistant steel material, and the hardness of normalizing, quenching and tempering with advanced equipment reaches HRC52-58. Advanced flaw detection technology is used to check the depth of each section of track, so that the whole track has the characteristics of anti-wear, anti-weight and so on.

These tractor loader bucket pins are manufactured using top-grade materials, and their sturdy construction makes them resistant to wear, tear, and corrosion.

With 26 drive teeth, this premium Bulldozer sprocket is a direct replacement that seamlessly aligns with your drive motor, making installation hassle-free.

With its seamless integration into your excavator system, our track roller facilitates smooth and efficient movement, allowing you to complete your projects with utmost proficiency. Its optimized design minimizes friction, thereby maximizing productivity, reducing downtime, and enhancing overall operational efficiency. Roller shell material: 50Mn/40MN2 Surface hardness: HRC50-56 Quench depth: =6mm Roller shaft material: 45# 142crmo Surface hardness: HRC52-56 Quench depth: > 2mm Collar material: QT450 - 10

The Loaders Track Roller is easy to install and maintain, reducing downtime and maximizing productivity. Regular inspection and lubrication of the roller ensure its smooth operation and extend its service life. Roller shell material: 50Mn/40MN2 Surface hardness: HRC50-56 Quench depth: =6mm Roller shaft material: 45# 142crmo Surface hardness: HRC52-56 Quench depth: > 2mm Collar material: QT450 - 10

Our Chain Link Sprocket ZX870 is a crucial component that engages with the bushing of the track link assembly, efficiently driving the entire excavator.

Dear customer friends The 2024 Shanghai BMW Expo will make a major comeback at the Shanghai New International Expo Center from November 26 to 29, 2024. After a four-year hiatus, Huamao Machinery sincerely invites you to visit the exhibition site and have face-to-face communication with us. Whether you are seeking cooperation opportunities, understanding industry trends, or have any questions or suggestions about our products and services, we will wholeheartedly provide you with the most professional answers and thoughtful services. Please pay attention to our exhibition information, reserve valuable time, and visit our booth. Thank you again for your attention and support. Looking forward to meeting you! 26TH-29TH NOV.2024 huamao machinery equipment Your best choice of undercarriage parts in China!

Read MoreFrom November 26th to 29th, bauma CHINA2024-Shanghai BMW Construction Machinery Exhibition officially opened the curtain of the four-day exhibition at the Shanghai New International Expo Center. Known as the weathervane of the construction machinery market, the Bauma Exhibition attracted 3,542 exhibitors from 32 countries and regions around the world, and more than 200,000 visitors from more than 160 countries and regions. The Bauma Exhibition demonstrated the vigorous vitality of global construction machinery companies, and also witnessed the innovation and transformation of construction machinery products and technologies. After a four-year absence, Huamao Machinery once again participated in the Bauma China, presenting a number of heavy-duty products at the exhibition. Some pictures of the products in the booth. There was an endless stream of new and old customers from home and abroad at the exhibition site, and Huamao Machinery was favored by many customers for its super high cost performance! Some pictures of customers communicating at the booth. Since its establishment in 2004, Huamao Machinery has been committed to R&D, production, sales, and service, specializing in the production of "four wheels and one belt" parts for crawler engineering machinery such as bulldozers, excavators, drilling rigs, cranes, road pavers, and tunneling machines. Huamao Machinery innovates its products, strives for excellence in quality, and provides attentive after-sales service. Huamao Machinery reaped a lot of benefits at this Bauma China. Huamao Machinery has always adhered to the development concept of "survive by quality and achieve efficiency by management", deeply cultivated the domestic and international markets, and continuously provided customers with high-quality services to empower enterprises and brands.

Read MoreEnter the specialized and special new enterprise In 2011, Quanzhou Huamao Machinery Equipment Co., Ltd. was established. In the 12 years since its establishment, the company has always focused on the core components of the high-end equipment manufacturing industry. "Four wheels and one belt" such as rollers, guide wheels, driving wheels, supporting sprockets, and chain/track assemblies are its main products. Up to now, the product market share ranks among the top in the province. In 2021, Huamao Machinery will enter the ranks of national-level specialized and new "little giants". "Specialized and special new enterprises usually have specialized technical products in specific fields, with unique market positioning and competitive advantages." In the view of Su Shaoxiong, deputy general manager of the enterprise, Huamao Machinery's "unique skill" lies in continuously advancing technology In addition to innovation and product innovation, it also has the ability to independently develop equipment. "It is both an equipment user and an equipment developer, so that the equipment can better adapt to the company's own needs, thus reducing company costs, improving production efficiency, improving product quality and stability." Self-developed production equipment Machine replacement process optimization In recent years, Huamao Machinery has maintained a steady development trend. Introducing lean management, optimizing production processes, and promoting technological innovation are one of the driving forces for the stable development of enterprises. "Under the pressure of economic downturn, rising labor costs, and raw material market fluctuations, corporate development is facing challenges." Su Shaoxiong said frankly that in order to cope with market challenges, the company launched lean production very early, eliminated waste by using limited resources, and continued to invest in automation Equipment, implementation of technical transformation and other means to continuously promote process optimization, improve production efficiency, and improve product accuracy and stability. It is understood that from last year to October this year, Huamao Machinery has introduced 10 sets of automation equipment. The links that originally required manual loading and unloading have been gradually replaced by robotic arms, further realizing the automation of machining. However, it is clear that Huamao Machinery does not want to stop at simply purchasing general-purpose equipment. In view of the pain points and blockages in the company's production process, the company independently develops personalized equipment that is closest to its own needs, thus forming a core competitiveness that is different from other companies. "In the past, many production links required different equipment to complete. The separation between production links and the need for materials to flow between equipment will affect production efficiency, as well as product quality and precision." Su Shaoxiong told reporters that they have established 10 people While maintaining an equipment R&D team, it also cooperates with Fuzhou University and other scientific research institutes to carry out industry-university-research cooperation to independently complete design, components, assembly, debugging, test runs, etc. "As of now, there are more than 20 self-developed equipment, covering drilling. There are three major categories: integrated boring and boring, integrated drilling and milling, and heat treatment. These equipment reduce the flow of materials and improve production efficiency and product quality by integrating the originally separated production links." The optimization of processes also comes from the rearrangement of space. "Originally, equipment for drilling, milling, boring and other production links were scattered in different areas, and the logistics between links caused a waste of time and personnel." Su Shaoxiong said that in order to eliminate time waste, they assembled different equipment into "lines" according to the production process. , to complete the optimization of the production process flow. "In the past, one employee could only be responsible for two pieces of equipment, but now one employee can be responsible for six pieces of equipment." Coordinated development Become a leading enterprise supplier Iterative innovation of products is a powerful "weapon" for enterprises to explore new markets. It is understood that over the years, Huamao Machinery’s annual R&D investment has accounted for approximately 4% of revenue. R&D expenses last year amounted to more than 16 million yuan. As of now, the company has 44 valid patents. "We have been committed to transformation and upgrading, and continue to carry out technological innovation from the process level." Su Shaoxiong told reporters that innovation is the "confidence" for enterprises to expand into new markets. "We adhere to the domestic and international dual-circulation route. 30% of our products are sold domestically and 70% are sold overseas." It is reported that since its establishment, Huamao Machinery has been deeply engaged in its main business and practiced its "internal strength". In expanding the aftermarket of domestic and foreign accessories, On this basis, in 2015, Huamao Machinery began to promote cooperation with leading companies in supporting facilities. "Becoming a supplier of leading enterprises and developing collaboratively with leading enterprises is a booster for the accelerated growth of small and medium-sized enterprises." Su Shaoxiong said frankly that these leading enterprises have strict standard systems. Before becoming its supplier, they will inspect and evaluate the company, then select an intended company and provide guidance and help the company build a system and establish corporate standards. Only when companies meet their requirements can they finally be added to their supplier list. "Every time customers visit, they often ask questions. We also learn and grow while improving and meeting customer needs one by one." It is understood that Huamao Machinery's products have been exported to Europe, Japan, South Korea, etc., and the company is also actively exploring new markets such as the United States. At present, the company has become a parts supplier for more than ten leading OEMs such as Hitachi, Doosan, Sany Heavy Industry, and XCMG.

Read MoreXinhua News Agency, Las Vegas, USA, March 14 (Reporters Huang Heng and Tan Jingjing) The 36th Las Vegas Construction Machinery Exhibition opened on the 14th. China's leading construction machinery companies sent a strong team to participate in the exhibition. The Las Vegas Construction Machinery Show is one of the three major construction machinery exhibitions in the world, held every three years. This exhibition attracted more than 1,800 construction machinery and supporting companies from around the world to participate in the exhibition. It is not only large in scale, but also reflects the trend of the entire industry's transformation towards electrification and intelligence. More than 150 Chinese companies including XCMG, Zoomlion, Sany Heavy Industry, Liugong, and Sunward Intelligent participated in this exhibition. At the exhibition, innovative concepts such as digital operation, intelligent on-site operation control, and remote control operation based on high-speed Internet of Things, drone assistance, full-angle scanning sensing and other technologies have been implemented into complete sets of equipment and products. At the same time, green energy and environmental protection concepts are deeply embedded in product design concepts. Including Chinese equipment manufacturing companies, major manufacturers around the world have launched intelligent solutions that help improve the efficiency of engineering operations. They will display or deliver new all-electric equipment to customers during the exhibition, such as all-electric trucks, excavators, etc. Machines, bulldozers, loaders and mining equipment, etc.

Read MoreChina's excavator exports face challenges again. Recently, the British Trade Remedy Agency (TRA) issued an announcement to initiate anti-dumping and countervailing investigations on Certain Excavators originating in China at the request of British companies. Domestic demand in the construction machinery market is sluggish this year, and overseas markets have become an important source of income. Products including Sany Heavy Industry, Xugong Machinery, Liugong, etc. are exported to the UK. How much impact will the above-mentioned double-reverse incidents have on relevant companies? What are the countermeasures? Many relevant companies responded that export sales in the British market accounted for a relatively small proportion and the impact was limited. The relevant person in charge of Sany Heavy Industry told reporters from the Financial Associated Press that they have paid attention to this development and will respond to it in a unified manner under the guidance of the China Electromechanical Association. It is expected that it will have a certain impact on the sales of Chinese excavators in the UK in the short term, because its main purpose is to pass this double-reverse investigation and finally impose additional tariffs. In the long term, in the context of increasing global trade frictions, Chinese companies may accelerate the deployment of overseas production capacity. 01 The UK plans to launch a double-reverse investigation into China’s domestic excavators On November 15, 2023, the British Trade Remedy Agency issued an announcement to initiate anti-dumping and countervailing investigations against Certain Excavators originating in China at the request of the British company JCB Heavy Products Ltd. The investigation period of this case is from July 1, 2022 to June 30, 2023, and the damage investigation period is from July 1, 2019 to June 30, 2023. The British customs code of the product involved is 8429521000. Interested parties in the case can register on the TRA website It is a self-propelled track-laying (i.e., crawler) excavator with a superstructure that can rotate 360° and an operating weight of 11,000 kilograms (i.e., 11 tons) or more. The content of the document is disclosed: The applicant claims that the alleged dumping has caused damage to the British industry through its impact on several aspects, including: profitability, market share, depressed prices, and growth. The British TRA investigation was launched with the announcement of anti-dumping (case AD0047) and countervailing (case AS0046) filings. According to the British anti-dumping and countervailing regulations, the relevant enterprises involved in the case should complete the stakeholder response registration within the prescribed time announced by the investigation agency (generally 15 days from the date of the "Announcement on Registration"), otherwise they will be regarded as non-cooperating enterprises. , may receive punitive tax rates and lose the UK market. 02 Domestic enterprises responded: The impact is expected to be limited, and overseas factory construction may be accelerated. "In the short term, it may have a certain impact on the sales of Chinese excavators in the UK." A relevant person in charge of Sany Heavy Industry told a reporter from the Financial Associated Press that the company can only sell less than 1,000 excavators in the UK a year. Comparing a set of data, according to Haitong Securities research report statistics, Sany Heavy Industry exported 33,500 excavating machinery in 2022, a year-on-year increase of 46.02%, accounting for 30% of China's total excavator exports, and excavating machinery export sales were 18.08 billion yuan. A year-on-year increase of 69%. According to this estimate, excavator sales in the UK market account for less than 3%. LiuGong responded on the interactive platform: The company's excavators are mainly produced and exported domestically, and there is no low-price dumping. Moreover, the overseas revenue of British excavators only accounts for about 2%, and the overall impact is limited. In addition, according to Interact Analysis's China non-road equipment import and export tracking database (data caliber is customs import and export data, including second-hand equipment): In the first three quarters of 2023, my country's excavator exports performed well. A total of 151,000 units were exported, a year-on-year increase of 22.8%, which accounted for 91.0% of last year’s export volume. The cumulative export value increased by 15.6% year-on-year to 46.51 billion yuan. Among them, crawler excavators are the main driving force, with exports accounting for 97%. The top ten excavator export destination countries accounted for 60.2% of the overall export volume, with the United States being the largest, accounting for 16.5%, followed by Belgium and Russia. In terms of export value, the top ten accounted for 59.7%, with Russia leading the way, accounting for 14.4%. From the comparison of data, relatively speaking, the British market is a "small" market. Previously, statistics from the Tianfeng Securities Machinery Team showed that Europe, ASEAN, and Asia-Pacific were the main export regions, and North America, South America, and Europe had higher growth rates. The above-mentioned relevant person in charge believes that in the medium to long term, more and more global trade frictions may accelerate the construction and layout of overseas production capacity of Chinese companies. First, it can better deal with trade frictions; Second, we will select the areas where we will build factories overseas. Taking into account the overall cost-effectiveness, we will not add too many (overseas) areas; Third, it will also be of great benefit to domestic enterprises in improving their capabilities in the global aftermarket. Because after the entire global production capacity is operational, the adequacy rate of the entire optional accessories will also increase a lot. The Financial Associated Press has noticed that leading construction machinery companies have all experienced development from the local to overseas. Take Caterpillar as an example. Caterpillar began its global layout in 1950, setting up its first overseas subsidiary in the United Kingdom, and gradually entering markets in Europe, Asia-Pacific and other regions to build overseas manufacturing bases. It has offices or subsidiaries in 40 countries and regions around the world and can provide support to customers in nearly 100 countries. However, after years of development, Caterpillar's influence in the market has gradually declined, with a market share of about 16%. This reason is inseparable from the rapid growth of my country's construction machinery. In particular, many Chinese brands such as Zoomlion Heavy Industry, Xugong Machinery, and Sany Heavy Industry have gone global, and their influence has continued to expand. Excavators are not only self-sufficient, but also exported overseas in large quantities. Statistics compiled by reporters from the China Federation of Finance and Economics show that domestic construction machinery manufacturers have been actively promoting their internationalization strategy through "overseas factory construction + acquisitions and mergers" for many years. For example, Sany Heavy Industry: Sany India was established in 2006; Sany America was established in 2007; Sany Europe was established in 2009, including a series of industrial chains such as production bases and R&D centers; Sany Brazil was established in 2010, mainly engaged in excavating machinery, Hoisting Machinery. XCMG Machinery: It has 5 international research centers, 15 overseas manufacturing bases and KD factories, and 30 overseas subsidiaries. It has established more than 2,000 service terminals and more than 5,000 marketing service personnel, covering 191 countries and regions. Zoomlion: It has established subsidiaries in East Asia, Southeast Asia, Europe and other regions, invested in and built industrial parks in Italy, Germany, Brazil, India, and Belarus, plans to build new factories in Turkey and Saudi Arabia, and has established more than 50 plants around the world. Resident institution. Centered on the United Arab Emirates and Brazil, it is gradually establishing a global logistics network and spare parts supply system. LiuGong: In 2012, LiuGong spent RMB 350 million to successfully acquire the civil engineering division of HSW Company in Poland. As a world-renowned manufacturer of heavy construction machinery and bulldozers, HSW's gear transmission technology is in a leading position in the world. Overseas manufacturing has established factories in India, Poland, Brazil, Argentina and other countries. 03 How will we deal with double-reverse violations in the future? Data statistics show that since 2012, the number of excavators exported by my country has been equal to the import volume. In 2018, the export volume of excavators exceeded the import volume for the first time. Since then, the export sales of excavators have maintained a high-speed trend. In 2022, the national export sales of excavators will be 109,500 units, a year-on-year increase of 59.8%. While the overseas export of domestic excavators is accelerating, the relevant British departments have launched anti-dumping and countervailing investigations on excavators originating in China, which has also sounded an "alarm bell" to domestic companies aiming to expand their overseas market share. According to industry insiders, the main purpose of this double-refugee investigation is to pass the investigation and finally impose additional tariffs. A reporter from the Associated Press of Finance noted that, in fact, a few days ago, the China Chamber of Commerce for Import and Export of Mechanical and Electronic Products issued an "early warning". According to the Ministry of Commerce's "Regulations on Responding to Anti-dumping Cases of Export Products", the China Chamber of Commerce for Import and Export of Mechanical and Electronic Products is responsible for anti-dumping in this industry. Coordination work of responding organizations. In order to help companies understand the relevant situation and prepare for the response in advance, the "Notice on Convening an Early Warning Meeting on the UK's Plan to Launch Anti-dumping and Countervailing Investigations against Chinese Excavators" was issued. Earlier this week, the European Commission announced it had opened an investigation into imports of mobile elevating work platforms (MEWPs) from China, following formal complaints from European suppliers that low-cost or "dumped" imports were harming the continent's industry Benefit. Based on the latest financial reports, major domestic construction machinery companies have exported different products overseas, including excavators. In terms of overseas share, in H1 this year, Sany Heavy Industry (56.88%), Xugong Machinery (40.75%), Zoomlion (34.78%), Liugong (43.17%), and Shantui Group (51.61%). Relevant British authorities have launched anti-dumping and countervailing investigations on Certain Excavators originating in China. How will domestic companies respond in the future? The above-mentioned relevant person in charge said, "Relevant companies will respond in a unified manner under the guidance of the China Electromechanical Association."

Read MoreLabor Day is one longiest holiday in China, we'll stop working from May. 1st to 5th. It is longer for students. It is a holiday that honors the contributions and achievements of workers. It serves as a reminder to appreciate the value of labor, recognize the rights of workers, and celebrate the dignity of work. Its origins can be traced back to the labor movement in the late 19th century. The holiday began as a way to recognize the social and economic achievements of the labor force, advocating for shorter working hours, safer working conditions, and fair wages. The Haymarket Affair in Chicago in 1886 played a significant role in the establishment of Labor Day. Today, Labor Day is celebrated with parades, picnics, and various activities, serving as a reminder of the importance of the labor movement and the rights of workers. Labor Day is now celebrated in various countries around the world, each with its own unique traditions and customs. We'll meet friends, stay with family mumbers, cook some delicious food and eat together. As we celebrate Labor Day, let us take a moment to express gratitude for the laborers who have shaped the world we live in. May this day serve as a reminder to strive for better workplaces and a more equitable society, where the dignity of work is upheld for all.

Read MoreIn the spring of March, spring is warm and flowers are blooming. Facing the vibrant spring weather, the employee birthday parties of KMF Company in February and March came as scheduled. On this special day, nearly a hundred people gathered together to celebrate birthdays, share joy, and feel the warmth and strength of the team. The friends from the Enterprise Management Department carefully arranged the event site, decorated it with lights, and filled the table with a variety of snacks and drinks. Everything was ready and waiting for the birthday stars to appear. 1. Warm-up games A birthday party is indispensable with cheerful games, including small quizzes on rules and regulations, production safety, etc., guessing numbers and other small games. Everyone helps each other and cooperates with each other. There are surprises, jokes, interactions, friendships, and carefully prepared "small prizes". The scene is full of laughter and atmosphere! 2. Talent display Of course, the birthday girls who are hiding in the dark are indispensable to show off their "art" style. You just finish singing and I will appear on the stage. Warmth is the accompaniment, and joy is the main theme. The stress of work and life is also released, leaving behind pieces of laughter! 3. Birthday celebration session In the familiar music, the birthday party came to a climax: a joyful birthday song, a warm blessing, a sweet cake, a thoughtful birthday gift box... these all represent The most sincere feelings! By holding a collective birthday party, Huamao family members can feel the warmth of the company, enhance friendship among colleagues, and improve employees' sense of belonging and cohesion. At the same time, it also injects new vitality into the company's cultural construction. Deep affection is not as good as long-term companionship, and deep love needs no words. In the future, we will continue to walk together and jointly build a team full of affection and love, full of centripetal force and cohesion. Finally, I wish all the birthday stars of Huamao a happy birthday! Embracing sincerity and enthusiasm, high-five the new year with happiness, and shine brightly on the Huamao stage!

Read MoreLoving yourself is the beginning of a lifelong romance. At every age, you are the right one. A daughter, a wife, a mother, and more importantly, yourself. On Women’s Day, pay tribute to every special “her”! Spring is in full bloom, and International Women’s Day is here as scheduled. KMF Company extends its most sincere holiday blessings to all the female employees who work hard and silently devote themselves to various positions, and wishes every "her": no confusion at twenty, no fear at thirty, no fear at forty, and no sigh at fifty. , I am only sixty, I have enjoyed the sweetness of life, and I am not afraid of the hardships of the years. I am not trapped by the outside world, not confused by my age, walk firmly, and roam freely! The flower language of carnations is sincere, respectful and warm blessings, chocolate represents love and the sweetness of life, bird's nest and white fungus are refreshing and nourishing. The company leaders, on behalf of the company, personally give each female employee a holiday gift carefully prepared by the company. May the small gift be with The half-day holiday brings a day of fragrant mood to every "her"! Queens of KMF Company, no matter which role you play, whether as a mother, wife, daughter in life, as a leader or employee at work, I hope you will not be afraid of time, brave the wind and waves, and move forward firmly!

Read More

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Add: Pudang Village, Xiamei Town, Nan'An City, Quanzhou, Fujian, China

Quanzhou Huamao Machinery Equipment Co.,Ltd All Rights Reserved.  Network SupportedSitemap | blog | Xml | Privacy Policy

Network SupportedSitemap | blog | Xml | Privacy Policy